Solar energy is a popular renewable energy source in Australia. Most of the solar panels available in the market are used for home solar panel systems. It is of mainly three types of solar panels: Monocrystalline, polycrystalline, and thin-film panels.

The solar cells present on the panels determine their types and each type of solar cell has different characteristics.

Major Types of Solar Panels

Most of the solar panels currently available in the market fit into three main categories:

- Monocrystalline panels

- Polycrystalline panels (also known as multi-crystalline)

- Thin-film panels

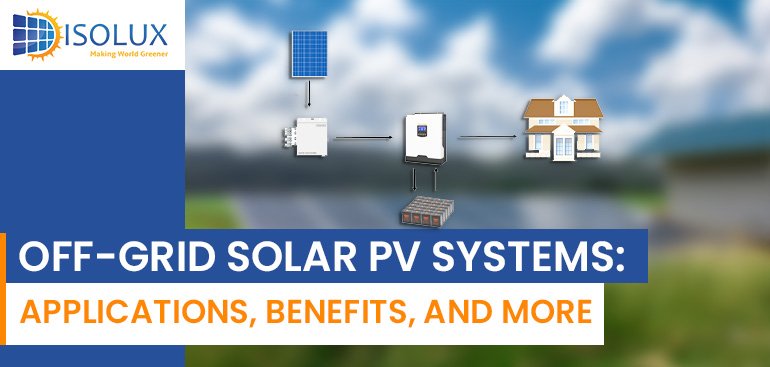

All these solar panels convert incident solar energy into electricity. Each solar panel consists of several solar cells, which are made up of silicon. When photons strike the surface of solar panels, electrons are knocked out of the silicon. This produces a directional electric current.

The solar panels differ from each other in the following parameters:

- Appearance

- Use

- Performance

- Cost

- Installation

- Efficiency

Each type of solar panel has its own pros and cons. When you hire Isolux Solar the best solar company in Sydney, the type of solar panel to be installed will depend on factors that are specific to your house and the system characteristics you need.

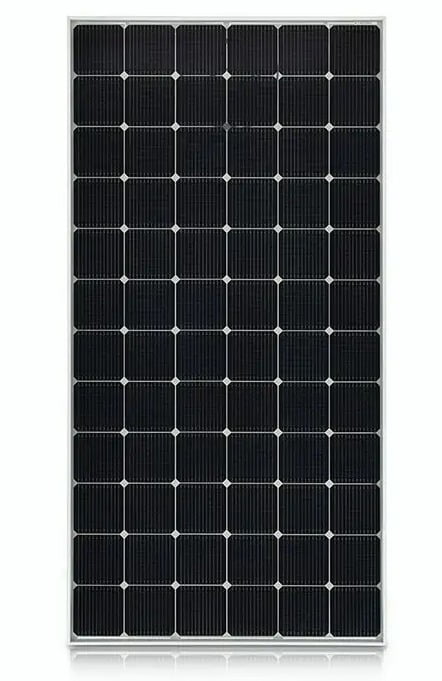

Monocrystalline Solar Panels

As the name indicates, these types of solar panels are made from a single silicon crystal. They are also known as single-crystal panels. A pure silicon crystal is sliced into several wafers, which are cut into octagonal-shaped wafers. This gives them their unique and uniform appearance and colour (full black or dark blue).

The pure silicon composition of monocrystalline solar panels allows more space for electrons to freely move in the solar cells, making them the most efficient of all solar panels (15–20% efficiency). Since the manufacturing process of monocrystalline solar panels is complex and energy-intensive, they are quite expensive compared to other types of solar panels.

Polycrystalline

They are made up of multiple silicon crystals; hence, they are also known as multi-crystalline solar panels. They are manufactured from melted silicon fragments that are poured into moulds. Once cooled, they are sliced into thin wafers and assembled into a polycrystalline solar panel. These types of solar panels lack uniformity and have pixelated, shining blue square-shaped cells with straight edges.

Compared to monocrystalline panels, they are more affordable since the manufacturing process is simpler. However, they have a lower efficiency than monocrystalline panels (15–17% efficiency).

Thin-film Solar Panels

They are manufactured using photovoltaic substances.

- Amorphous silicon (a-Si)

- Copper indium gallium selenide (CIGS)

- Cadmium telluride (CdTe)

Thin layers of these photovoltaic substances are deposited on glass, plastic sheets, or metal, making them lightweight and easy to install. They are less efficient than silicon solar panels but comparatively cheaper as well. Commonly used for large utility-scale power plants.

With so many different types of solar panels available, the decision will be based on the specifics of your home (property) and application.